-

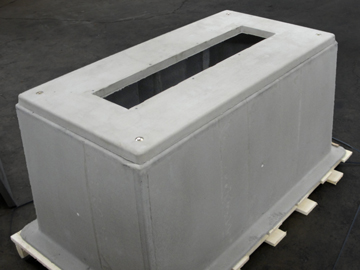

Sectionalizer Box Pad -

Installed Transformer & Box Pad -

An Array of Different Box Pads -

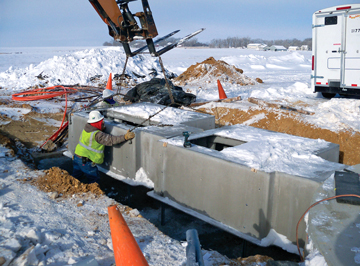

IT Box Pad Being Installed at Wind Turbine Base -

Multi-Opening Box Pad -

Box Pad Being Manipulated Via Fork Lift -

Fibercrete® Sectionalizer Bases -

Fibercrete® Sectionalizer Bases -

Box Pad Hardware Close-up Photo -

Stack of Fibercrete® Box Pad Dividers on a Pallet -

Three Boxpads Being Installed at a Job Site -

Installation of a Box Pad -

Electrical Gear Set onto a Concast Box Pad -

Interior View of Electrical Equipment Mounted onto a Box Pad -

Box Pad With Bolt-Down Cover -

IT Box With Custom Galv. Steel Access Cover -

Interior View of Box Pad Knockout -

Sectionalizer Box Pad with Flat Pad -

Close-Up of Bolt-Downs on the Sectionalizer Box Pad & Flat Pad Assembly -

Non-Standard Sizes of Box Pads Can be Achieved Via the Use of Split Technology -

Two Sections of Split Box Pad are Bolted Together -

Curved Fibercrete® Tunnel Opening Covers -

Modular (Piggy-Back) IT Box Pad Installation -

Custom Openings Can Be Built Into Sidewalls for Applications Such Trench Entry -

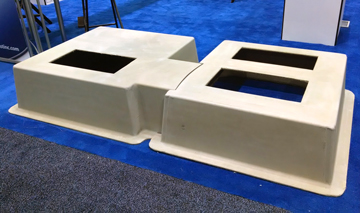

1/4 Scale Modular Box Pads at the Concast Trade Show Booth -

Above Ground Vista SwitchGear Installation -

Transformer and Integrated Tunnel Box Pad Installed at Wind Turbine Base -

Unistrut Leveling System

Concast P/N:ULS for Windfarm IT Box Pads